In previous blog entries on this subject, we have discussed the general nature of the hazard of lawn tractor rollovers and some of the statistics that have been compiled concerning them. We also have addressed the industry history of Rollover Protection Systems (ROPS) and its’ near 100% effectiveness in preventing death. We have also discussed some of the defenses which the tractor manufacturers have asserted in court to justify why they either do not have ROPS available or make them available only as extra optional equipment for an additional price.

Another defense asserted by the manufacturers is that the accident was caused by operator error. It is a matter of no dispute that these machines can roll over because of three basic causes:

- mechanical failure

- environmental conditions

- operator error

Therefore, it comes as no surprise to the manufacturers that these machines can be operated improperly which leads to a rollover accident. We have never contended in any of our court cases involving these injuries that the ROPS could serve to prevent the accident from occurring. Rather, it is much like a seatbelt and airbag in our automobiles. Those pieces of safety equipment do not prevent an accident from occurring. Rather, in the case that an accident does occur, the seatbelts and airbags in our cars prevent the injury from occurring or keep the injury from being more severe than it might be in the absence of such protective equipment. The analogy holds equally true for ROPS on lawn tractors. They will not prevent the accident from occurring but they prevent the “second collision” from causing the type of injury that would be caused in the absence of ROPS. In automobile litigation, this concept is known as “crashworthiness”.

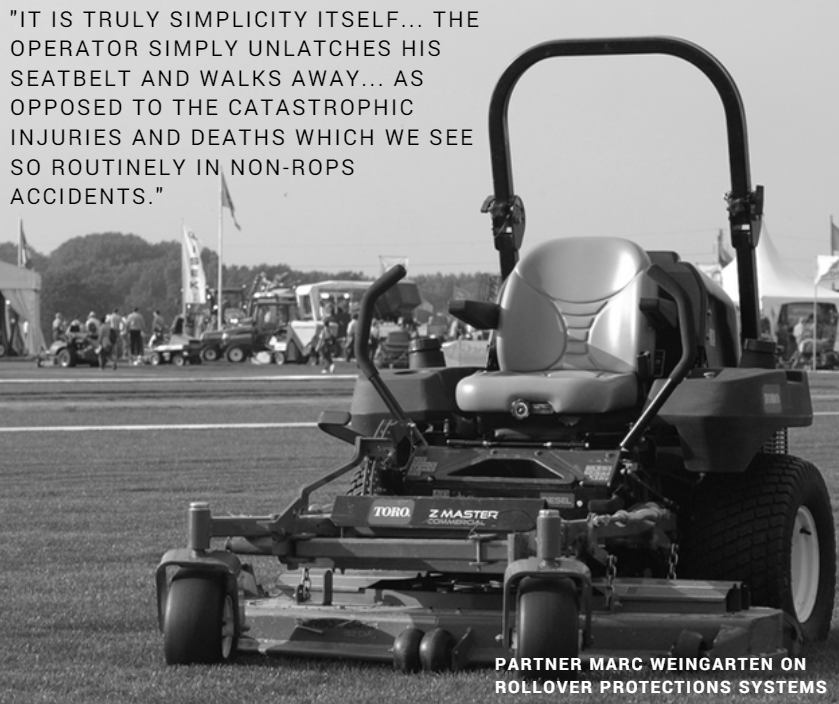

Let us examine the simplicity of ROPS. All that it requires is a roll bar overhead of the operator and a seat belt to hold the operator in place if there is a rollover accident.

If, for any reason, whether it be a mechanical failure, environmental conditions or operator error, the machine rolls over, the roll bar overhead would prevent the operator from being crushed by the weight of the equipment as it would essentially keep him within a metal cage or protective cocoon. Remember, when the machine rolls over, the roll bar, which during the course of ordinary operation is above the operator, would then switch positions and be under the operator, preventing the machine from landing on top of him and crushing him into the ground. In addition, the seatbelt would hold the operator in place so that he is not thrown from the machine in the course of the rollover.

It is truly simplicity itself. If there is a ROPS in use in the event of a rollover, the operator simply unlatches his seatbelt and walks away, with either no injury or minor injuries, as opposed to the catastrophic injuries and deaths which we see so routinely in non-ROPS accidents.

This seems pretty straightforward, doesn’t it?

More on this topic in our next blog entry.